Whether you’re tiling a wall, floor, shower enclosure, splashback or wetroom, the effectiveness of any tile installation depends quite a lot on the type of substrate you’re tiling onto. If the surface that is having tiles attached directly to it is uneven, not level, has dents and depressions, or is too porous then this can have an adverse effect on not only the finish of the project but its durability and longevity too. Plaster, plywood and MDF are all susceptible to various external influences including water damage, warping and structural failure. One surefire way to avoid all these things however is to use backer boards as your substrate. Here’s our handy guide on how to choose the right backer board for your tiling project.

What Are Backer Boards?

In the simplest of terms, backer boards are prefabricated sheets (commonly constructed from cement-based materials) that are attached to walls and floors to form a sturdy base onto which tiles can be laid. They usually come in two different thicknesses – 6mm and 12mm – with the former generally used for flooring installations and the latter for walls.

What Different Types of Backer Board Are Available?

Whilst all backer boards essentially serve the same purpose, there are some slight variation between the different types available:

Cement Backer Board

Cement backer board (also called cement board), is probably the most commonly used backer board for use in ceramic and porcelain tile installations. Constructed primarily of cement and reinforced with fiberglass, this type of board is waterproof and so is mostly used for tiled shower surrounds and enclosures, wetrooms and floors in areas exposed to direct water. No More Ply is a popular brand of cementitious backer board.

Fiber Cement Board

Fiber cement board (also called fiber board), is constructed from Portland cement mixed with sand and cellulose fibers. Fiber board is recommended for floor tile installations as the make-up of the board helps adhesives to bond with the board itself. Fiber cement board is most commonly available in 1200×800 sized sheets and in 12mm and 6mm variants. One of the most well-known manufacturers of this type of board is James Hardie who produce the HardieBacker range of cement boards.

Polystyrene-Based Insulation Board

This type of board is not strictly a backer board, although it is designed to be tiled directly onto and is lightweight yet sturdy. The main selling point of this type of board however is their heat conducting and waterproofing properties – they’re ideal for use with underfloor heating and are often the choice for wetrooms and commercial applications such as pools, spas and steam rooms. Norcros Pro Board is a popular product within this category.

Glass Reinforced Cement Sheets (Mat Gypsum Board)

This type of backer board is constructed from water-resistant gypsum that has been treated with silicone and reinforced with fiberglass mats on the surface of each side. This type of backer board is lighter than cement board and is intended for use in areas that are susceptible to being exposed to water.

Water-Resistant Drywall

Another that is not considered backer board, water-resistant drywall can still be tiled on directly and is acceptable for use in areas where occasional splashes may occur but which are otherwise dry. Water-resistant drywall is less expensive than cement or gypsum backer board, but it can be easily damaged by water ingress and so shouldn’t be used in areas that are subjected to direct water over a long period of time.

Which Type of Tile Adhesive Should Be Used When Tiling Onto Backer Boards?

As backer boards are essentially separate block panels attached to a substrate (such as flooring joists) they’re subject to slight movement. As such, when installing ceramic, porcelain or natural stone tiles directly onto them you should always opt for a flexible adhesive such as Mapei Keraquick. Some backerboard manufacturers also produce flexible adhesives designed specifically for use with their backer board products – No More Ply Adhesive being one example.

Are There Any Special Considerations To Be Made When Using Backer Boards?

Other than ensuring you’re using a type of backer board that is suitable for the type of installation you’re carrying out, there’s not much else to take into account. If deploying backer boards in wet areas you should always ensure that you make any joints watertight using waterproof joint tape such as HardieBacker Fibatape.

It’s also worth remembering that some types of backer board require priming ahead of installation – always check the manufacturer’s instructions before starting a job. Finally, it is sometimes worth investing in the cutting tools some manufacturers produce for use with their backer boards – products such as the HardieBacker Score & Snap Knife make cutting boards to size a lot easier. For thicker/denser boards an angle grinder may be required.

Backer Boards Are Load Bearing, So How Much Of A Load Can Each Type Support?

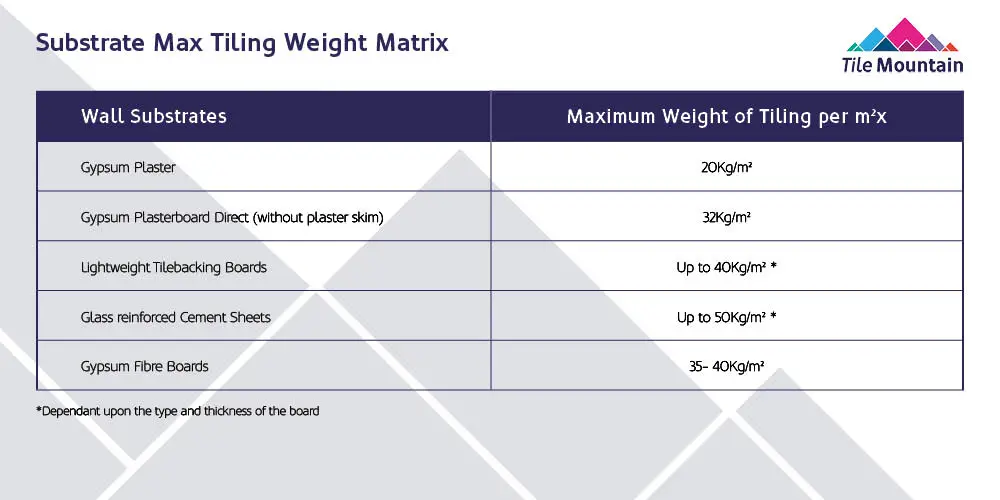

Each backer board will have this information either embossed or printed on the boards themselves or on the packaging, so always check the limitations of your particular board before installing. Generally speaking though, the loads for each board are similar to the below:

If you have any further questions about backer boards and their installation then please don’t hesitate to get in touch with our friendly customer services guys either via the LiveChat function or by calling 01782 223 822 – they’ll be more than happy to help with any queries. For more installation advice on all aspects of tiling then head over our Help Centre section – it’s packed full of help and advice and useful hints and tips!

Here at Tile Mountain, we not only have a huge range of tiles to suit every purpose, we also have a wealth of tiling knowledge gained from over 30 years in the tile industry, (which we’ll do or best to share with you across these very pages).

Whether you’re looking for the perfect tiles for your next home improvement project, are searching for some style inspiration, or simply need a bit of help and advice, you’re in the right place.